| Key Takeaways |

- PTFE seals offer exceptional chemical resistance and wide temperature range (-450°F to 600°F)

- SSI brand PTFE seals provide low friction and high durability

- Available in various types, including lip seals, mechanical seals, and custom solutions

- Ideal for industrial, automotive, aerospace, and medical applications

- Shree Shakti Industries is a leading manufacturer of high-quality PTFE seals

|

# [PTFE Seals | Ahmedabad: High-Performance Sealing Solutions by SSI

## 1. Introduction to PTFE Seals

PTFE or Teflon seals are high-performance solutions for demanding applications across various industries. Shree Shakti Industries, a leading manufacturer and supplier under the “SSI” brand, offers a comprehensive range of PTFE seals that combine exceptional chemical resistance, wide temperature tolerance, and low friction properties.

### 1.1 Definition of PTFE Seal

A PTFE seal is a sealing device made from polytetrafluoroethylene (PTFE), a synthetic fluoropolymer of tetrafluoroethylene. These seals prevent leakage and contamination in various mechanical systems and equipment.

### 1.2 Overview of PTFE (Teflon) Material Properties

PTFE, commonly known by its brand name Teflon, offers unique properties that make it ideal for sealing applications:

– Exceptional chemical resistance

– Wide temperature range (-450°F to 600°F or -268°C to 315°C)

– Lowest coefficient of friction among solids

– Non-stick surface

– Excellent electrical insulation

### 1.3 Importance of PTFE Seals in Various Industries

PTFE seals play a crucial role in ensuring the efficiency, safety, and longevity of equipment across multiple industries, including:

– Chemical processing

– Food and beverage

– Pharmaceutical

– Automotive

– Aerospace

– Oil and gas

– Mining

– Electrical and electronics

– Medical and healthcare

## 2. Key Features and Benefits of SSI PTFE Seals

Shree Shakti Industries’ SSI brand PTFE seals offer numerous advantages:

1. **Chemical Resistance**: Inert to most chemicals and aggressive media

2. **Temperature Range**: Wide operating temperature range from -450°F to 600°F

3. **Low Friction**: Lowest coefficient of friction among solids, reducing wear and energy consumption

4. **Durability**: High wear and creep resistance for extended service life

5. **Safe for food processing applications**:

6. **Unlimited Shelf Life**: Long-lasting performance without degradation during storage

7. **Versatility**: Suitable for various applications and industries

8. **Cost-Effectiveness**: Reduced maintenance and replacement costs due to longevity

## 3. Types of PTFE Seals Offered by SSI

Shree Shakti Industries manufactures a wide range of PTFE seals to meet diverse application requirements:

– PTFE Lip Oil Seals

– PTFE Mechanical Seals

– PTFE Thread Seals

– PTFE Bellow Seals

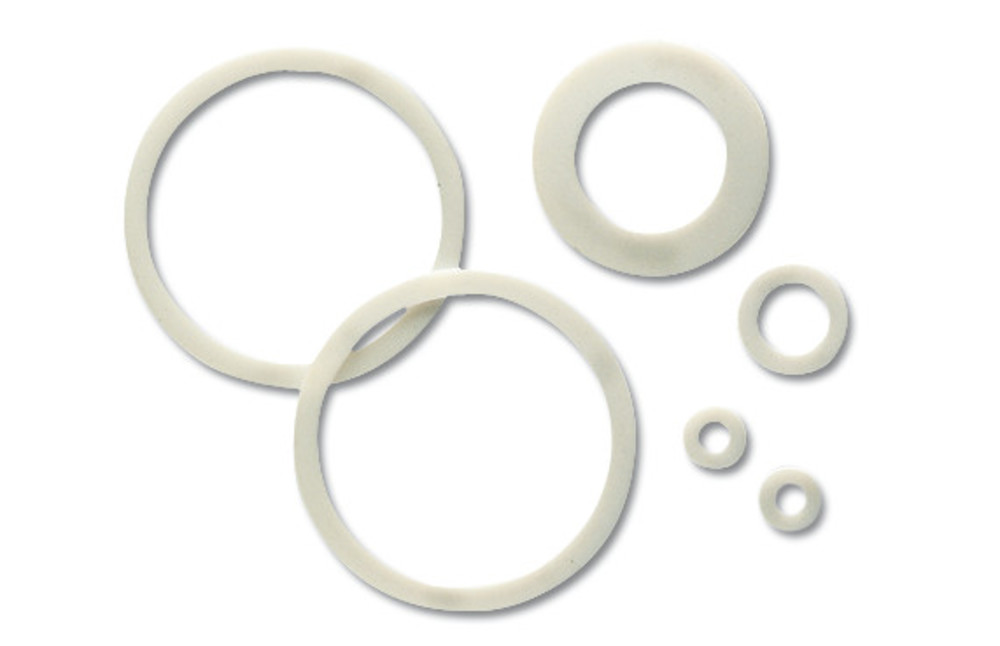

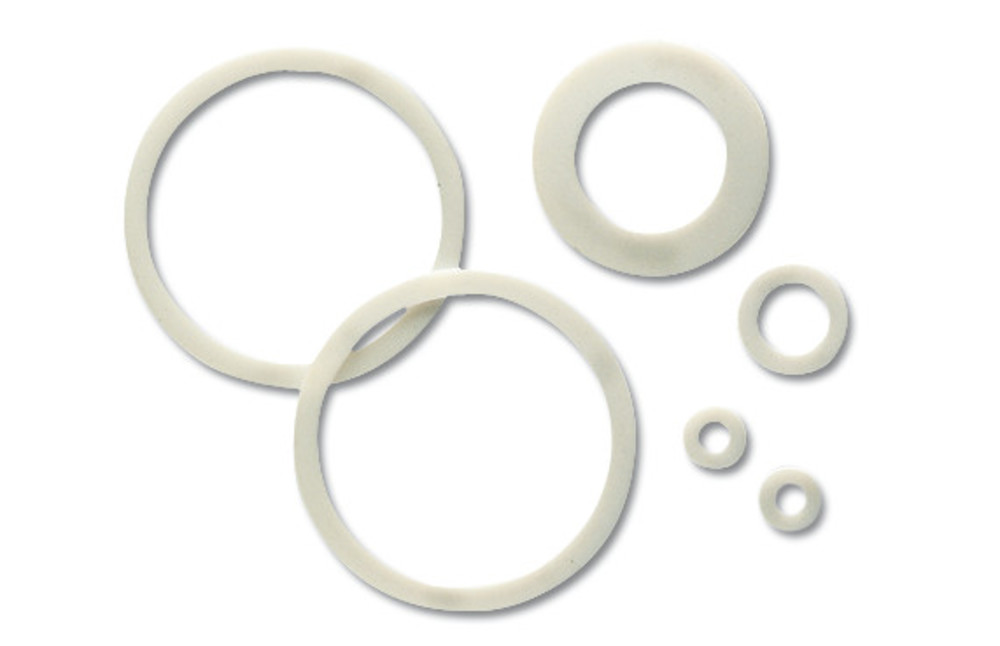

– PTFE Sealing Washers

– PTFE Packing Seals

– PTFE Piston Seals

– PTFE Radial Shaft Seals

– PTFE Rotary Lip Seals

– PTFE O-rings

– PTFE Gaskets

– PTFE Diaphragm Seals

– PTFE Rod Seals

– Custom PTFE Seals

### 3.1 PTFE Lip Seals

SSI PTFE lip seals are designed for rotary applications, offering excellent sealing performance in low- and high-speed conditions. Available in single-lip and double-lip configurations, these seals are ideal for automotive, industrial, and aerospace applications.

### 3.2 PTFE Mechanical Seals

Our PTFE mechanical seals provide reliable sealing for rotating equipment in various industries. They offer superior chemical resistance and can withstand high temperatures and pressures.

### 3.3 PTFE Thread Seals

SSI PTFE thread seals, including PTFE thread seal tape, ensure leak-free connections in threaded joints. They are widely used in plumbing, hydraulic, and pneumatic systems.

### 3.4 PTFE Bellow Seals

PTFE bellow seals from Shree Shakti Industries are designed for applications requiring flexibility and resistance to extreme temperatures and chemicals. They are commonly used in pump seals and expansion joints.

### 3.5 Custom PTFE Seals

SSI offers custom PTFE seal solutions tailored to specific application requirements. Our engineering team works closely with clients to design and manufacture seals that meet unique specifications.

## 4. Applications of SSI PTFE Seals

### 4.1 Industrial Applications

– Chemical processing equipment

– Food and beverage machinery

– Pharmaceutical production lines

– Compressors and pumps

– Fluid transfer systems

– Mixers and agitators

### 4.2 Automotive Applications

– Engine seals

– Transmission systems

– Fuel systems

– Brake systems

– Power steering components

### 4.3 Aerospace Applications

– Aircraft engines

– Hydraulic systems

– Fuel systems

– Environmental control systems

– Landing gear components

### 4.4 Oil and Gas Industry

– Downhole tools

– Subsea equipment

– Valves and fittings

– Wellhead equipment

– Pressure vessels

### 4.5 Medical and Healthcare

– Surgical instruments

– Autoclaves and sterilization equipment

– Pharmaceutical processing equipment

– Diagnostic devices

– Implantable medical devices

## 5. Technical Specifications of SSI PTFE Seals

### 5.1 Material Grades

SSI offers various PTFE grades to suit different application requirements:

– Virgin PTFE

– Glass-filled PTFE (15%, 25%, 40%)

– Carbon-filled PTFE (5%, 15%, 25%)

– Graphite-filled PTFE

– Bronze-filled PTFE

– Molybdenum disulfide-filled PTFE

### 5.2 Temperature Ratings

– Standard PTFE: -450°F to 500°F (-268°C to 260°C)

– High-temperature PTFE grades: Up to 600°F (315°C)

### 5.3 Pressure Ratings

Pressure capabilities vary depending on the seal type and design. SSI PTFE seals can handle pressures ranging from vacuum to 10,000 psi (689 bar) or higher for specialized applications.

### 5.4 Coefficient of Friction

PTFE offers an exceptionally low coefficient of friction, typically ranging from 0.05 to 0.10, depending on the specific grade and application conditions.

## 6. Installation and Maintenance of SSI PTFE Seals

### 6.1 Installation Guidelines

Proper installation is crucial for optimal performance of PTFE seals. SSI provides detailed installation instructions for each seal type, including:

– Surface preparation

– Lubrication recommendations

– Alignment procedures

– Torque specifications

### 6.2 Maintenance Tips

To ensure the long-lasting performance of SSI PTFE seals:

– Conduct regular visual inspections

– Clean seals and surrounding areas as needed

– Monitor operating conditions for any changes

– Replace seals at recommended intervals or if signs of wear are observed

– Follow proper handling and storage procedures to prevent damage

### 6.3 Troubleshooting Common Issues

SSI provides comprehensive support for troubleshooting seal-related problems, including:

– Leakage diagnosis

– Wear pattern analysis

– Performance optimization recommendations

## 7. Advantages and Disadvantages of SSI PTFE Seals

### 7.1 Advantages

– Exceptional chemical resistance

– Wide temperature range tolerance

– Low friction and wear

– FDA compliance for food-grade applications (As per requirement)

– Excellent electrical insulation properties

– Versatility across various industries

– Long service life

### 7.2 Disadvantages

– Higher initial cost compared to some traditional sealing materials

– Potential for cold flow under high loads

– Limited elasticity compared to rubber seals

– Requires careful installation to prevent damage

## 8. Comparing SSI PTFE Seals to Other Sealing Materials

### 8.1 PTFE vs. Rubber Seals

SSI PTFE seals offer superior chemical resistance and temperature range compared to rubber seals, making them ideal for harsh environments. However, rubber seals provide better elasticity and lower initial costs for less demanding applications.

### 8.2 PTFE vs. Other Elastomeric Seals

SSI PTFE seals excel in low friction, high-temperature resistance, and chemical compatibility compared to other elastomeric seals. They are particularly advantageous in applications where traditional elastomers may degrade or fail.

### 8.3 PTFE vs. Other Fluoropolymers

While other fluoropolymers like FKM (Viton) offer good chemical resistance, SSI PTFE seals generally provide superior performance regarding temperature range, friction reduction, and overall inertness.

## 9. Environmental Impact and Sustainability

### Eco-friendly PTFE Alternatives

SSI is actively researching and developing eco-friendly alternatives to traditional PTFE, including bio-based and recyclable materials, to meet growing sustainability demands.

## 11. Why Choose SSI PTFE Seals?

Shree Shakti Industries, under the SSI brand, offers several compelling reasons to choose our PTFE seals:

1. **Quality Assurance**: manufacturing processes

2. **Customization**: Tailored solutions to meet specific application requirements

3. **Technical Expertise**: Experienced engineering team for design and application support

4. **Competitive Pricing**: Cost-effective solutions without compromising on quality

5. **Quick Turnaround**: Efficient production and delivery times

6. **Comprehensive Product Range**: Wide variety of PTFE seal types and sizes

7. **After-Sales Support**: Dedicated customer service and technical assistance

## 12.2 Custom Orders

For custom PTFE seal solutions:

1. Contact our engineering team with your specifications

2. Receive a detailed proposal and quote

3. Approve the design and place your order

4. Benefit from our efficient manufacturing and quality control processes

## 13. Conclusion

SSI PTFE seals by Shree Shakti Industries offer high-performance sealing solutions for a wide range of industries and applications

. Our commitment to quality, innovation, and customer satisfaction makes us a leading choice for PTFE sealing solutions. With exceptional chemical resistance, wide temperature tolerance, and low friction properties, SSI PTFE seals provide reliable performance in even the most demanding environments.

Whether you need standard PTFE seals or custom-engineered solutions, Shree Shakti Industries has the expertise and capabilities to meet your sealing requirements. Our comprehensive range of products, technical support, and after-sales service ensure you receive the best sealing solution for your specific application.

## 14. Frequently Asked Questions (FAQs)

1. **Q: What is the difference between a PTFE seal and a Teflon seal?**

A: There is no difference. Teflon is a brand name for PTFE (polytetrafluoroethylene). SSI PTFE seals are made from the same material as Teflon seals.

2. **Q: Are SSI PTFE seals suitable for food-grade applications?**

A: Yes, our PTFE seals are FDA-compliant and safe for use in food processing equipment.

3. **Q: What is the temperature range of SSI PTFE seals?**

A: Our standard PTFE seals can operate from -450°F to 500°F (-268°C to 260°C), with high-temperature grades reaching up to 600°F (315°C).

4. **Q: How do I choose the right PTFE seal for my application?**

A: Consider operating temperature, pressure, chemical exposure, and speed. Our technical team can assist you in selecting the most suitable seal for your specific requirements.

5. **Q: Can SSI manufacture custom PTFE seals?**

A: We specialize in custom PTFE seal solutions tailored to your unique specifications.

6. **Q: How do PTFE seals perform in high-pressure applications?**

A: SSI PTFE seals can handle pressures from vacuum to 10,000 psi (689 bar) or higher, depending on the design and application.

7. **Q: What common fillers are used in SSI PTFE seals?**

A: Common fillers include glass, carbon, graphite, bronze, and molybdenum disulfide, each offering specific performance enhancements.

8. **Q: How should I install PTFE seals properly?**

A: Proper installation is crucial. We provide detailed installation guidelines for each seal type. Generally, ensure clean surfaces and proper alignment, and follow recommended lubrication and torque specifications.

## 15. Contact Information

For inquiries, technical support, or to place an order, please get in touch with SSI PTFE Products:

– Phone: +91-9462168772

– Email: ssiptfe@gmail.com

– Website: https://ssiptfeteflon.com

– Address: A-302/A, K.B. ROYAL HOMES O.P.P. SWATI-5 RESIDENCY, Chandkheda, Ahmedabad, Gujarat 382424

Our team of experts is ready to assist you with all your PTFE sealing needs, from product selection to custom design solutions.

By choosing SSI PTFE seals from Shree Shakti Industries, you’re partnering with a leader in sealing technology. Our commitment to quality, innovation, and customer satisfaction ensures you receive the best sealing solution for your application. Contact us today to discover how SSI PTFE seals can enhance the performance and reliability of your equipment.